Temperature measurement in hydrogen production

Non-invasive temperature measurement redefined with the iTHERM SurfaceLine TM611

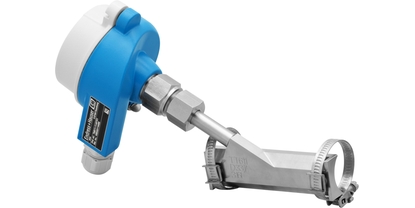

In some applications of hydrogen production invasive temperature sensors reach their limits. The iTHERM SurfaceLine TM611 by Endress+Hauser revolutionizes temperature measurement in hydrogen production with its noninvasive technology. This innovative solution provides precise and rapid measurements, minimizes the risk of leaks and contamination, and allows for easy installation without process interruptions.

Benefits

Accurate and quick measurement

Reduced or eliminated risk of leakages

Easy installation without opening the process

Availability of different communication protocols

The challenge

Hydrogen production has been developed for years and includes a variety of different process steps, such as water treatment, cooling and heating circuits, the electrolyzer or hydrogen storage and compression. Each of these steps involves different requirements and challenges for temperature measurement. Sometimes a simple sensor is sufficient, but for applications with high pressure or purified water, an invasive temperature sensor can cause many difficulties.

Our solution

For temperature measurement in hydrogen applications with high pressure and purified water, the non-invasive measurement iTHERM SurfaceLine TM611 is a cost-effective, maintenance-free and accurate alternative to invasive measurement with conventional measuring devices.

| FLEX セレクション | 技術的卓越性 | シンプルさ |

|---|---|---|

Fundamental セレクション 基本的な測定要件に対応 |

技術的卓越性

|

シンプルさ

|

Lean セレクション コアプロセスの要件に対応 |

技術的卓越性

|

シンプルさ

|

Extended セレクション 革新的な技術でプロセスを最適化 |

技術的卓越性

|

シンプルさ

|

Xpert セレクション 最も困難なアプリケーションにも対応 |

技術的卓越性

|

シンプルさ

高い柔軟性 |