In the transition towards a net zero economy, hydrogen is emerging as a promising energy carrier to reduce carbon emissions in the oil and gas industry. Hydrogen presents challenges for transport, storage and use, therefore expert consultation on accurate and reliable measurement is essential. Our portfolio enables safe operation with optimal performance while providing regulatory and environmental compliance with traceability and documentation.

Key facts

USD 80 billion

average annual global investment in H2 infrastructure to increase tenfold by 2050 (IEA)

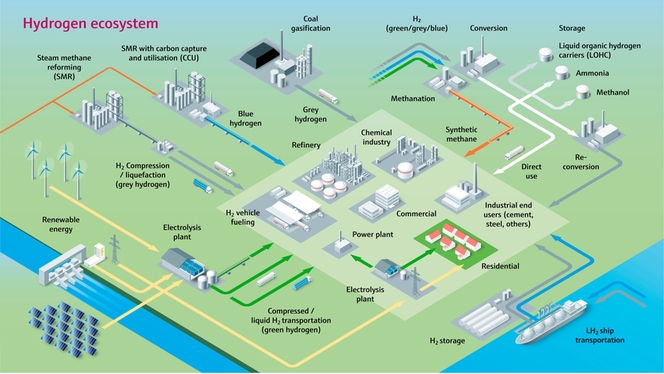

The hydrogen ecosystem

Hydrogen enables decarbonization, renewables integration, and zero-emission mobility. Its cleanliness and multi-sector applicability provide a holistic approach to clean energy. Global demand comes from refineries, ammonia production, and other industries. Hydrogen production sources include fossil fuels, industrial processes, biomass, and renewables. It is classified as grey, blue, or green based on its source and transported via pipelines, trucks, or ships in gaseous or liquid phase (LH2).

Hydrogen injection in natural gas grid

Hydrogen can be transported using the existing natural gas infrastructure depending on the pipelines. Every incremental amount of hydrogen injected into a natural gas fuel system or pipeline abates some amount of methane, and thus CO₂. Injection percentages can vary from 10-20% as per the regulations. Relying on accurate flow and composition measurement technology is critical to ensure both quantity and quality of the blends.

Our expertise in the field

By using Endress+Hauser Coriolis flowmeters, it is easy to measure with high accuracy, stability and ultimately control, the flow of hydrogen into the natural gas grid appropriately. To determine the final mix ratio, you can rely on

Measuring water quality for green hydrogen production

The electrolysis process requires ultrapure water. To produce 1 kg of hydrogen, 9 kg of ultrapure water is used, which means roughly 30 kg of seawater. Water not meeting quality requirements could impact smooth operation of the electrolyzer thereby increasing OPEX. Conductivity is the leading quality parameter. It is generally limited to <1 μS/cm for alkaline electrolyzers and <0.1 μS/cm for PEM electrolyzers.

Our expertise in the field

Sea water is a vital source considering scarcity of fresh water in parts of the world. Consequently, distinct treatment steps are necessary to achieve the required water purity for electrolyzer operation. The quality of the feedwater supplied to the reverse osmosis (RO) membrane needs to be closely monitored to control efficiency, trigger cleaning or regeneration and ensure adequate water quality. Endress+Hauser offers a wide range of sensors and analyzers to monitor these processes.

- Ease of use and flexibility make the multi-channel transmitter platform perfect for installations with multiple Memosens 2.0 quality sensors

- For alkali electrolysis, pH is used to maintain the caustic electrolyte solution; state-of-the-art Memosens 2.0 Technology ensures reliable operation and high uptime

- At industrial scale hydrogen plants, also the accurate monitoring of

LOHC – an easy way of hydrogen distribution and storage

Liquid Organic Hydrogen Carriers (LOHC) are organic compounds that will absorb and release hydrogen through chemical reactions. LOHC are considered a feasible method to store and transport hydrogen over long distances using the existing infrastructure.

Our expertise in the field

During both hydrogenation and dehydrogenation high temperatures occur. Several key measurement points are essential for monitoring and controlling the reaction. Endress+Hauser helps you ensure process efficiency, safety, and product quality.

- Broad portfolio of products, services, and solutions

- Coriolis, thermal and Vortex flow measurement devices with online, in-situ verification optimizing the hydrogenation processes

Servo displacer technology for liquid hydrogen Tank Gauging

Hydrogen storage in liquid form is a cryogenic process, therefore posing challenges for inventory measurement due to the extreme temperatures -253°C (-423.4°F), boil-off gas and vapor pressure. To ensure safe operation of the tank and precise inventory, reliable level gauges and independent alarm gauges for overfill are essential.

Our expertise in the field

Endress+Hauser

Steam methane reforming (SMR) and blue hydrogen

Steam methane reforming (SMR) is the most used process to produce hydrogen in refineries. Process challenges include high temperatures, the presence of a catalyst and the need to control the process with minimum variabilities. Blue hydrogen production involves SMR with carbon capture in the process chain.

Our expertise in the field

The Endress+Hauser portfolio helps you optimize your reforming process efficiency while reducing greenhouse gas emissions.

How we can help

It is important that highly reliable measurement instrumentation is used throughout the hydrogen value chain – from production to end use. To guarantee fair transactions and accountability, Coriolis meters must measure the amount of hydrogen transferred accurately. To comply with quality standards, hydrogen quality measurement also plays a crucial role. Endress+Hauser offers best-fit instrumentation and solutions for hydrogen production as well as liquefaction plants.

- Broad portfolio: high-performing measurement equipment from one single supplier

- We are unique in providing accurate and reliable quality, quantity and composition measurement

- State-of-the-art communication protocols available across all measurement points for seamless integration

- Easy installation and commissioning: Endress+Hauser Heartbeat Technology health monitoring allows for maintenance-free operation

- Data is verified, custody transfer proof and secure