- F

- L

- E

- X

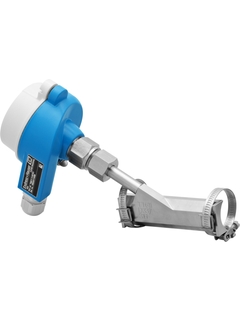

Version with aluminium terminal head TA30A, 20° angle, DN25, 1 ", outside pipe ⌀ 33.7 mm

- F

- L

- E

- X

Mounting on the outer pipe wall: elimination of leakages, process contamination, flow disturbance

- F

- L

- E

- X

Version with explosion-proof terminal head TA30H, 90° angle, DN150, 6 ", outside pipe ⌀ 168.3 mm

- F

- L

- E

- X

Version with explosion-proof terminal head TA30H, 20° angle, DN25, 1 ", outside pipe ⌀ 33.7 mm

- F

- L

- E

- X

Version with stainless steel terminal head TA30R, 20° angle, DN25, 1 ", outside pipe ⌀ 33.7 mm

- F

- L

- E

- X

Version with cable probe TST310, 20° angle, DN25, 1 ", outside pipe ⌀ 33.7 mm

- F

- L

- E

- X

Thermal coupling element with advanced geometry and heat transfer material for optimized heat transfer; stainless steel clamps for easy installation

- F

- L

- E

- X

Ideal for energy monitoring

Version with aluminium terminal head TA30A, 20° angle, DN25, 1 ", outside pipe ⌀ 33.7 mm

Specs at a glance

-

Accuracy

depending on application

Class AA acc. to IEC 60751

Class A acc. to IEC 60751

Class B acc. to IEC 60751

Class special or standard acc. to ASTM E230

Class 1 or 2 acc. to IEC 60584-2 -

Response time

depending on application

-

Operating temperature range

-196 °C…400 °C (-320,8 °F...752 °F)

Field of application

The non-invasive thermometer iTHERM SurfaceLine TM611 is used across all industries to measure temperature without the risk of leakage and process disruption. The device is safe and easy to install and provides the same accuracy and response time as invasive temperature measurement. A specially designed thermal coupling element provides ideal thermal conductivity to the sensor and reduces ambient influences, resulting in superior measurement performance even compared to electronic compensation.

Can be used universally in all industries

Ideal for demanding process conditions such as high flow velocities, high process pressures, highly viscous or corrosive media, abrasion, pigging or small pipe diameters

Perfect for subsequent installation for measurements in existing facilities for energy and safety monitoring

Benefits

Measurement accuracy and response time comparable with invasive measurements

No process opening required, no leakage risk

Increased safety for personnel, plant and the environment

User-friendly from product selection to installation and maintenance

Significant cost savings: shorter development and project planning times, reduced expenses for installation, certification and inspections as well as no costs for thermowells, nozzles and flanges, weld seam inspections and pipe extensions.

iTEMP temperature transmitter with all standard communication protocols and optional Bluetooth® connectivity

International certification: e.g. explosion protection according to ATEX, IECEx, CSA and NEPSI; functional safety (SIL)

Videos

-

Explore our unique product design and components

-

Comparison with invasive thermometers: accuracy and response time

-

Benefits of iTHERM SurfaceLine TM611

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

-

Measuring principle

Resistance Temperature Detector

-

Characteristic / Application

non-invasive thermometer

cable probe or modular thermometer

suitable for high process pressures

surface mounting -

Thermowell / protection tube

without (not intended to use with thermowell)

-

Insert / probe

non exchangeable RTD or TC insert

-

Outer diameter protection tube / Insert

Geometry of coupling element is designed according to diameter of process piping

-

Process connection

surface mounting

-

Operating temperature range

-196 °C…400 °C (-320,8 °F...752 °F)

-

Accuracy

depending on application

Class AA acc. to IEC 60751

Class A acc. to IEC 60751

Class B acc. to IEC 60751

Class special or standard acc. to ASTM E230

Class 1 or 2 acc. to IEC 60584-2 -

Response time

depending on application

-

Integration head transmitter

yes (4 … 20 mA; HART; iO-Link, PROFINET, PROFIBUS PA; FOUNDATION FIELDBUS)

-

Ex - approvals

ATEX IECEx Ex tb, Ex ia, Ex db

CSA C/US IS, NI

UKCA Ex tb, Ex ia, Ex db -

Certification

SIL, MID, Marine

Choose from our suggested options

-

-- selected coding-- selected label99.999,00<%label%>

-

Looking for more options? Please use the individual configurator to continue

-

-- selected coding-- selected label99.999,00<%feature%>

-

<%label%>99.999,00

-

Looking for more options? Please use the individual configurator to continue

-

Process Connection

-

<%label%>99.999,00

-

<%label%>99.999,00

-

-

<%feature%><%coding%><%label%>

- CAD drawings CAD drawings

- CAD drawings

-

Prices per piece

-

<%range%><%price%>

-

- Optional add-ons

Individual configuration

Often bought together

Accessories

Related products